1. Introduction

In the electrolytic aluminum and electrochemical industry, the cost of electrolytic production is high in the proportion of electricity price. Saving electricity can reduce production cost, strive for greater profit. Recently, many large power users are considering setting up their own "microgrids". That is, using the isolated power grid rectifier technology. In this situation, because the thyristor has the ability to adjust the current quickly, stably and accurately, only using the high-power thyristor rectifier can it accommodate to the load change (low frequency load reduction) caused by the generator set in the power plant. That is to say, it can save more cost of electricity by the high-power rectifier power supply technology in the isolated power grid.

The rectifier device for aluminum electrolysis in the power supply mode of isolated power grid is an independent rectifier system developed by our company. The results of the project can be widely used under the power supply mode of the isolated power grid in the coal, electricity and aluminum integration project, and electrolytic aluminum projects where clean and renewable energy sources such as wind or solar power are combined with traditional thermal power. Its rectifying efficiency is 2% higher than that of the traditional diode rectifier system, and it has remarkable energy saving effect. The popularization of the project achievement can drive the transformation from traditional electrolytic aluminum diode rectifier to the thyristor rectifier which is powerd by the isolated power grid supplied with renewable energy.

2. Project case

The second phase of a technical reform project in Northwest China — an electrolytic aluminum project with an annual output of 2×450,000 tons.

Description of works:

After the completion of the project, there are 6×300MW generator units running parallel to build an internal microgrid ( the isolated power grid), which directly supplies power to two aluminum electrolysis series through the 330kV generatrix.

Aluminum electrolysis series adopts 500kA electrolytic cell, each series installs 336 sets, rated voltage is 1480V. The system is connected to the external large power grid through a 330kV dedicated circuit, and can provide two aluminum electrolysis series with emergency standby power supply not higher than 500MW.

3. Product advantages

The main technical advantages are as follows:

3.1 The intelligent digital technology is used to combine the total control system, the split-flow regulation steady current control system, the constant power control, the frequency modulation and load reduction technology etc. into a control system organically.

According to the change of power supply and load, the automatic switching uses different operation modes such as steady current control and constant power control, which can ensure the safety of the power plant generator and meet the need of stable operation of the electrolytic cell.

3.2 This project adopts thyristor digital intelligent steady current technology, digital frequency modulation and load reduction technology of power network. The thyristor digital steady current system makes the rectifier have the advantages of fast response time and wide range of load regulation, which makes the speed and effect of digital frequency modulation and load reduction of power grid better.

After the aluminum electrolysis project used this technology in the isolated power supply mode, the AC side power grid is more stable because of digital frequency modulation and load reduction technology, the steady current effect of DC side current is better, and the precision of steady current is up to 0.2% because of thyristor digital intelligent steady current technology. Compared with the diode rectifier equipment without this technology, the electricity consumption can be saved by 2% in the production process of aluminum electrolysis, and the energy saving effect is remarkable.

3.3 The digital pulse control technology has strong magnetic field resistance. The thyristor rectifier uses pulse opening angle to steady the current. The digital PID operation can improve the steady current effect and the response speed greatly. The higher the stability of DC power supply in electrolytic aluminum is, the higher the production efficiency will be. The digital steady current control system can effectively improve the production efficiency of electrolytic aluminum.

3.4 The recurrent protection function of the newly developed thyristor rectifier device can make the thyristor achieve the effect which of diode state at the moment of high voltage tripping, fully release the energy storage, and protect the safety of DC power supply equipment.

3.5 The industrialization and application of high-power rectifier isolated power grid supply project conforms to the energy-saving technology of boiler, kiln, reactor and related energy consumption equipment in the field of energy saving and environmental protection; and new technologies and equipment in the field of new energy and renewable energy, such as wind energy、 solar energy.

The product of this project fills the technology blank in China, the technical level reaches the international leading level, greatly enhances the competitive power of the product in domestic and foreign market .

4. Pictures of projects

4.1 Power grid system

4.2 Rectifier cabinet device in order

4.3 Control system in centralized placement

5. Latest cooperation projects

In running:

Phase II electrolytic aluminum project of Jia-jiu wind power high-load characteristic aluminum alloy energy-saving technical reform project with the annual production of 2×450,000 tons of Jiugang Group Gansu Dongxing Aluminum Industry Co., Ltd.

Series 3 and Series 4 electrolytic aluminum project of Xinjiang East Hope Group

Non running:

Electrolytic aluminum project of Guangxi Hualei new material co., Ltd with the annual production of 450,000 tons

Electrolytic Aluminum Project of Inner Mongolia Huayun New material Co., Ltd. with the annual production of 500,000 tons

Electrolytic Aluminum Project of Inner Mongolia Chuangyuan Aluminum Industry Co., Ltd. with the annual production of 450,000 tons

Electrolytic Aluminum Project of Guizhou Xingren Denggao Aluminum Industry Co., Ltd. with the annual production of 500,000 tons

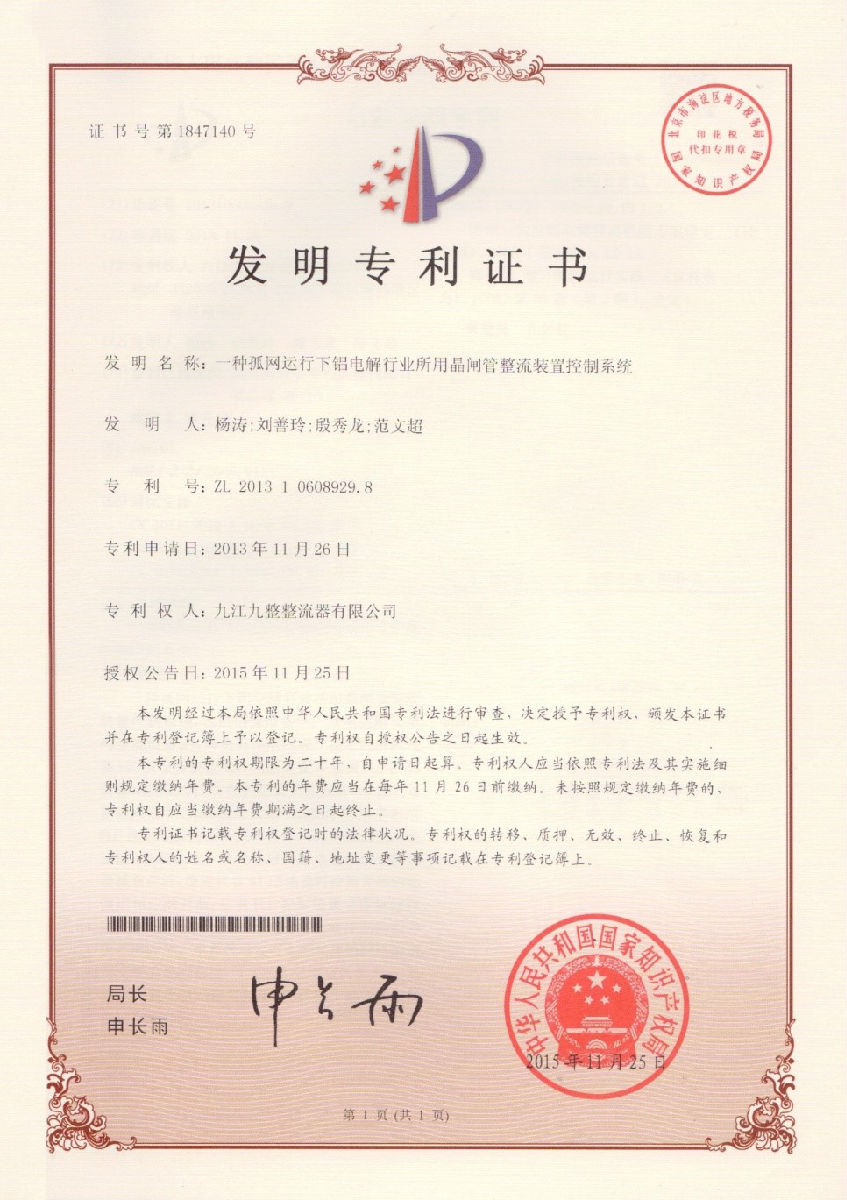

6. Project achievement

obtained 1 invention patent

A control system of high power thyristor rectifier for aluminum electrolysis under isolated power grid operation patent number:ZL201310608929.8